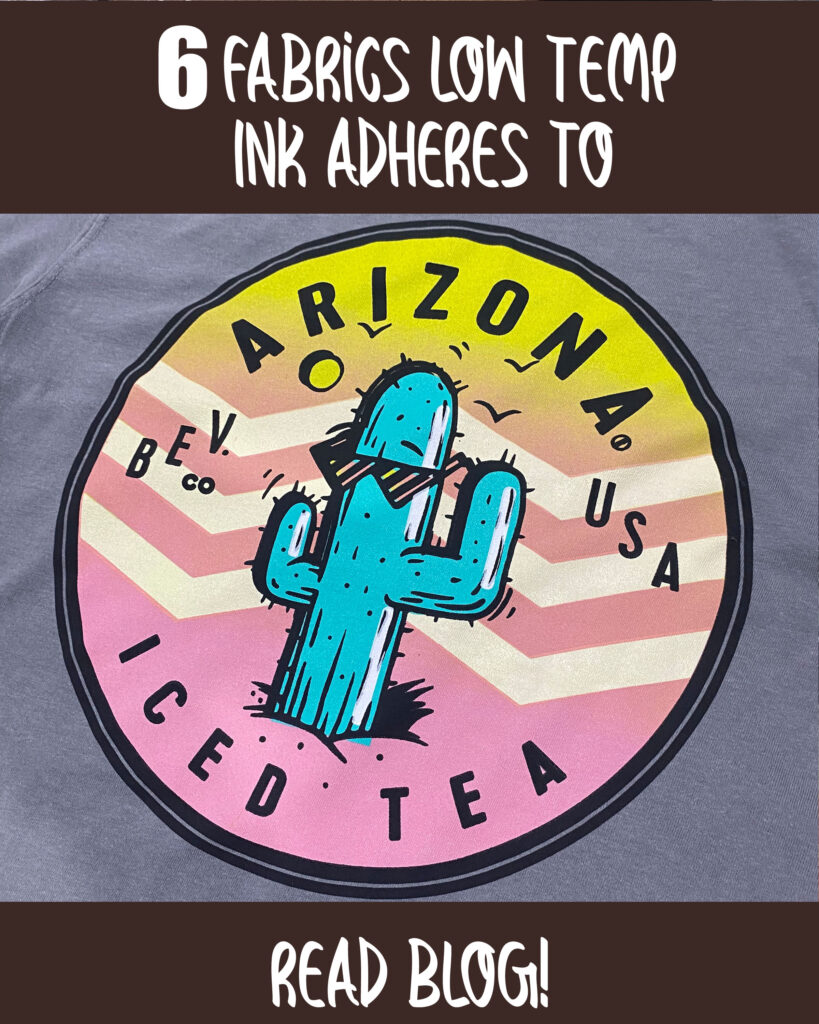

6 Fabrics Low Cure Ink Adheres to

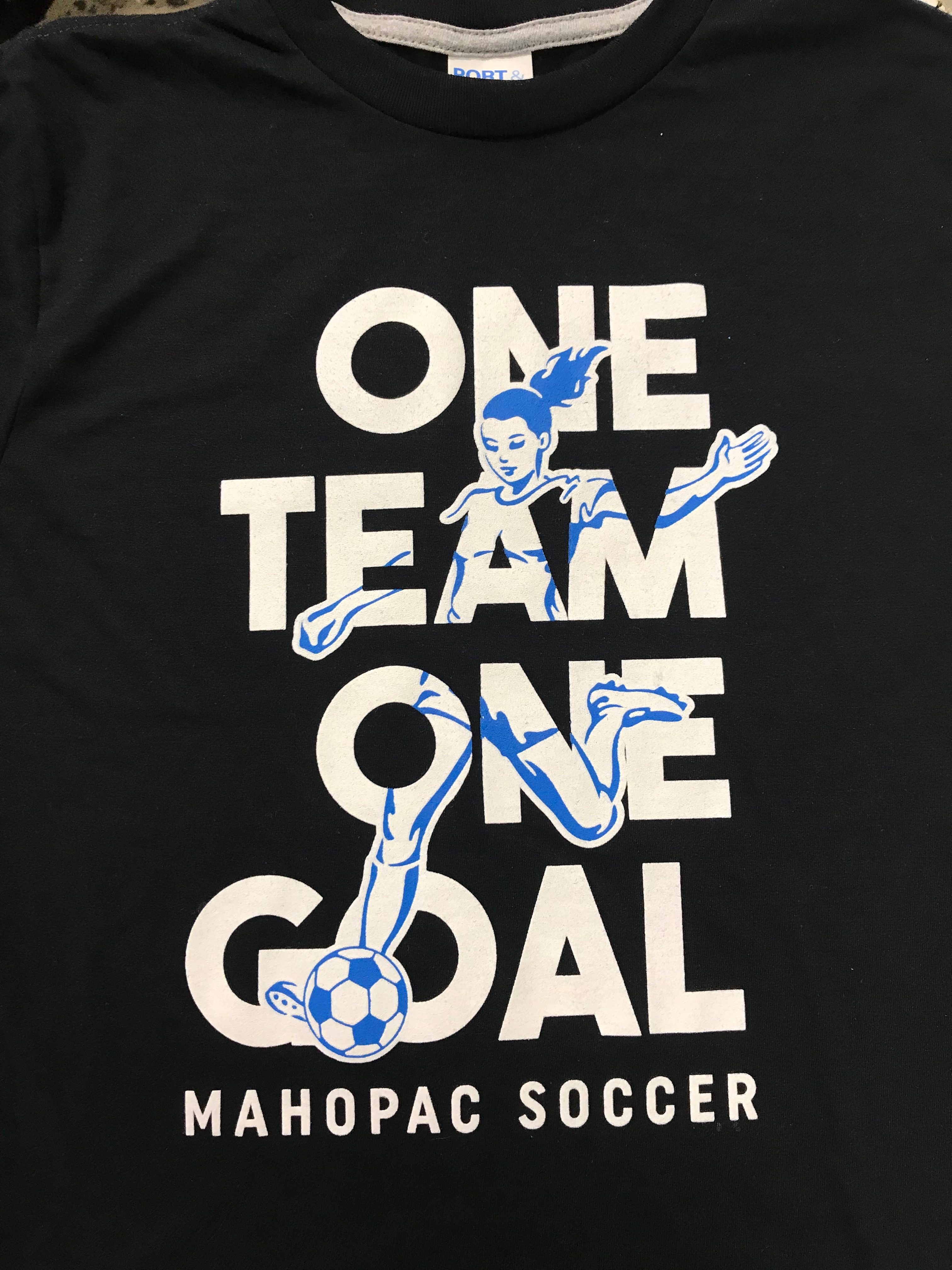

Low temperature ink cures at 260 degrees Fahrenheit without a catalyst. Lowering the dryer temperature enables you to screen print on all fabrics from polypropylene and nylon to cotton and 50%/50% sweatshirts. The ink is easy to use, super soft, and creamy. Results are crisp, clean, beautiful, and bold. There is nothing like our ink. Game changer!!

3. Prevents Nylon from Shrinking.

3. Prevents Nylon from Shrinking.