Our low cure ink is now BIODEGRADABLE! The ink cures at

Our low cure ink is now BIODEGRADABLE! The ink cures at

260°F and can print on ALL fabrics.

-

Higher Quality Prints. Switching to Fusion 180° will enable you to achieve a crisp and clear finish. Lowering the temperature of your dryer to 260°F allows you to print on heat sensitive materials. Screen print with our low temperature ink for a beautiful and bold print with excellent opacity and coverage as shown in the photo below.

-

Won’t Have to Worry About Ink Expiring. Fusion 180 does not require a catalyst, which means you will not have to worry about ink expiring, therefore saves time and money.

-

Increase Production. You can cure Fusion 180° with a flash, increasing production.

-

Save Money. You will save money by not having to replace garments damaged by high heat or dye migration. You will also be able to lower the temperature of your dryer, saving energy.

-

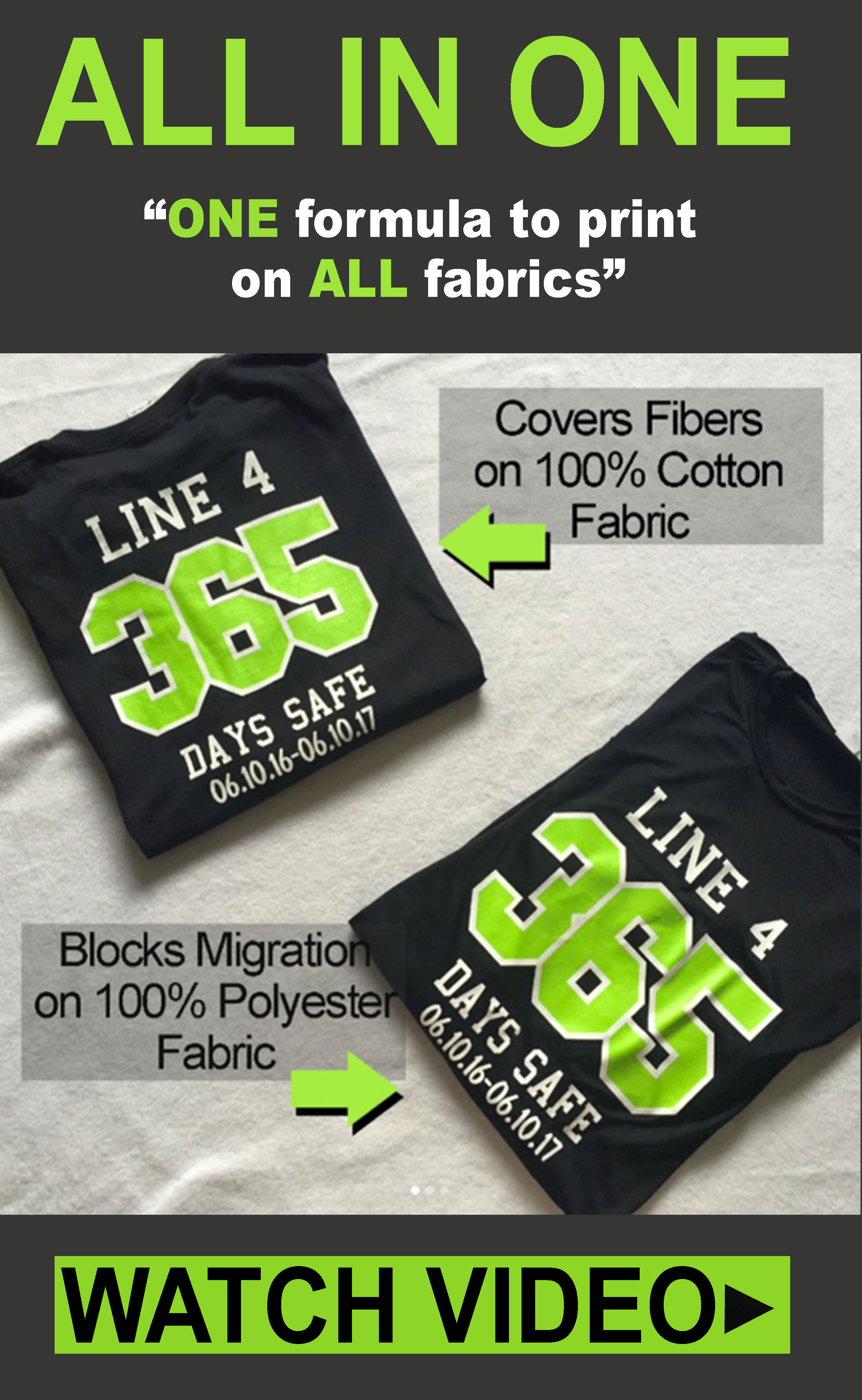

Print on all fabrics. The ink covers fibers on cotton, blocks migration on polyester and sublimated polyester, adheres to thicker fabrics including raincoats, will not shrink nylon or non woven bags, and prevents scorching on 50/50 sweatshirts.

Save Time. Save Money. Switch to Fusion 180 Low Temp Ink TODAY!