6 Helpful Tools for Your Screen Print Shop

Fusion 180 is a one-stop shop for all of your film, tape and ink needs. Listed below are six helpful tools for your screen print shop!

-

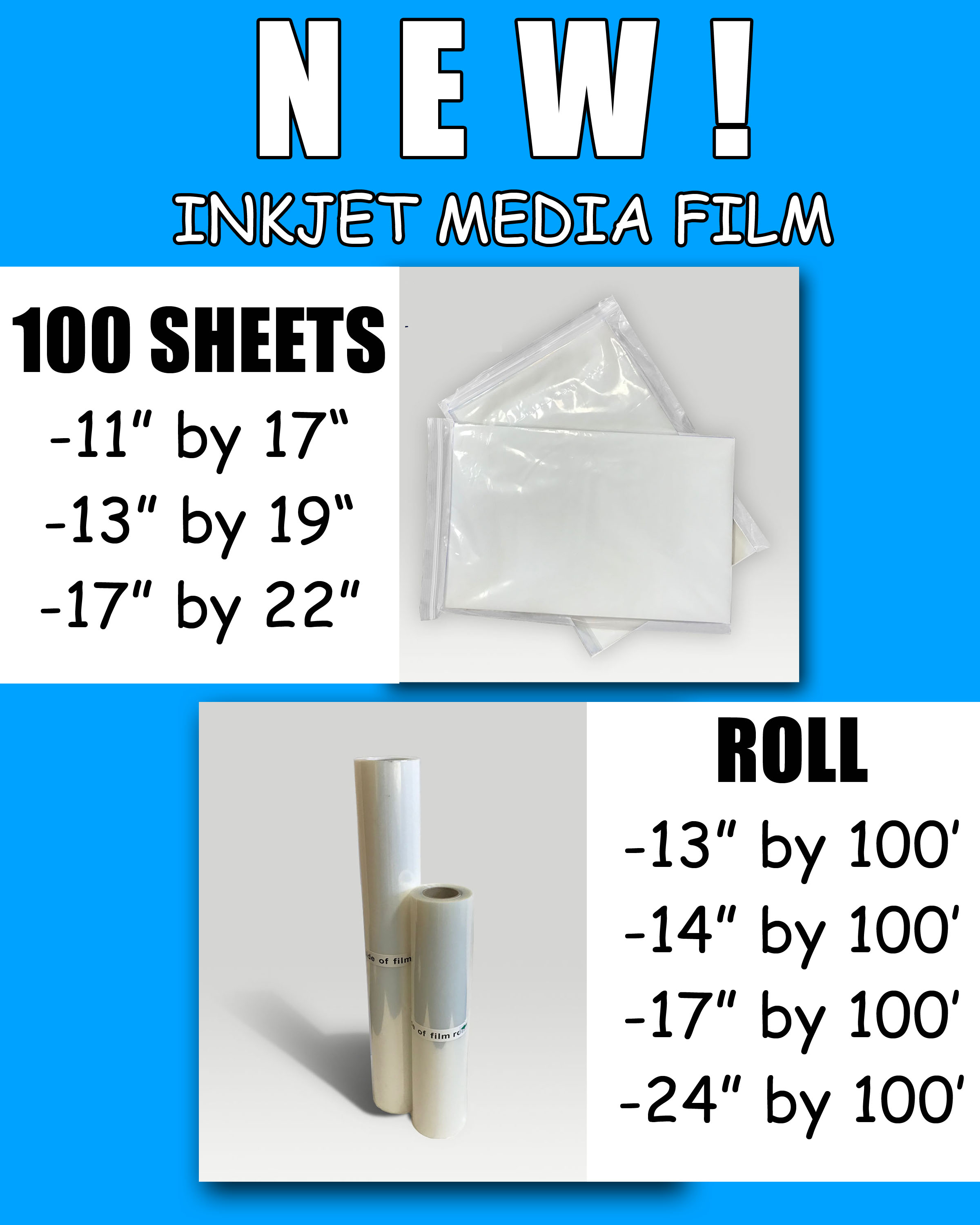

Inkjet Media Film

Our waterproof inkjet media film is high quality, used for your screens, and competitively priced. SHEETS | ROLLS

-

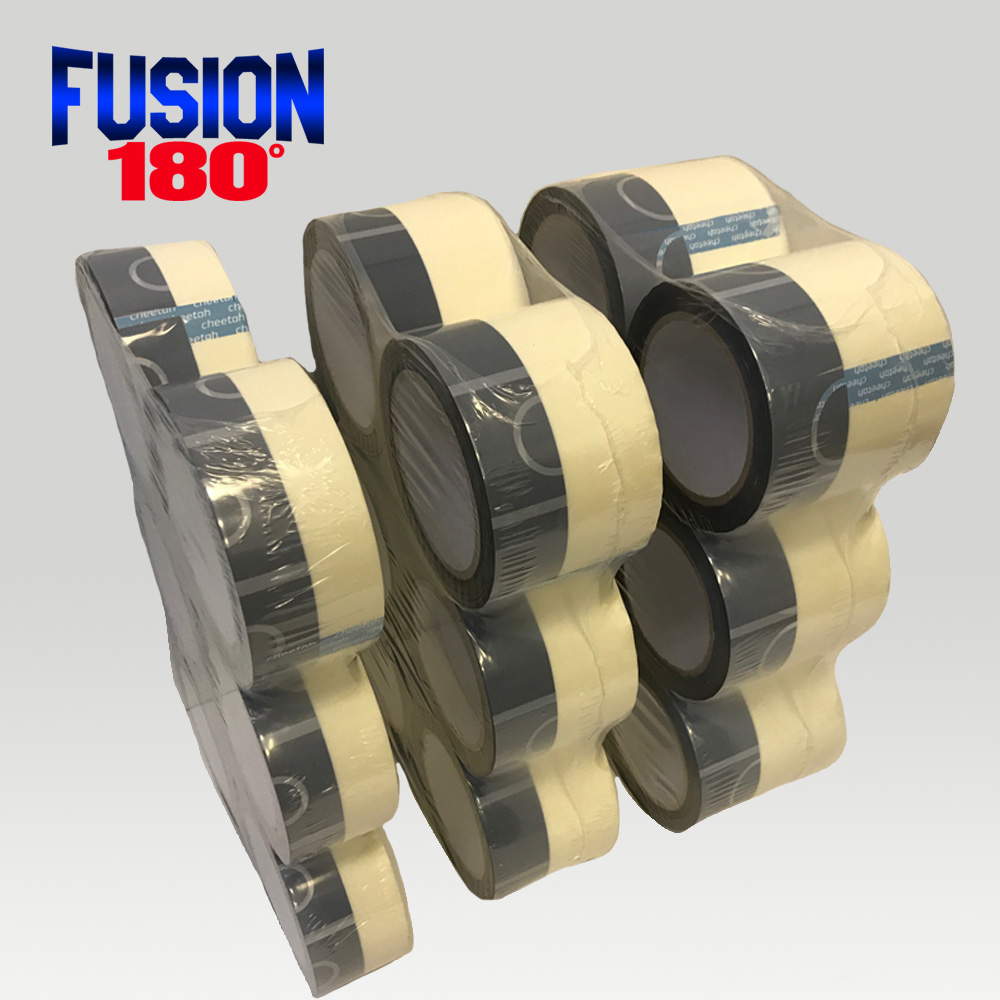

Split Tape

Our split tape is used to block ink smearing out of screen frame. The tape is made with a combination of Polypropylene, Polyisophorone, and Hydrocarbon resin. The white section has natural rubber adhesive, and the black portion doesn’t. We offer 2″, 3″, and 4″ split tape. The tape peels off easily from the screen without damaging photo emulsion and will not leave residue on the screen. The natural rubber adhesive provides a long shelf life. SPLIT TAPE.

Our split tape is used to block ink smearing out of screen frame. The tape is made with a combination of Polypropylene, Polyisophorone, and Hydrocarbon resin. The white section has natural rubber adhesive, and the black portion doesn’t. We offer 2″, 3″, and 4″ split tape. The tape peels off easily from the screen without damaging photo emulsion and will not leave residue on the screen. The natural rubber adhesive provides a long shelf life. SPLIT TAPE. -

Fusion 180

Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save money by not having to replace garments damaged by high heat or dye-migration? Look no further… Fusion 180° was created to solve all of these issues. All you have to do is lower the temperature of your dryer.

Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save money by not having to replace garments damaged by high heat or dye-migration? Look no further… Fusion 180° was created to solve all of these issues. All you have to do is lower the temperature of your dryer.Listed are 17 facts about Fusion 180° ink:

-

Our ink is now biodegradable

-

Proper mesh and curing temperature depends on the thickness of ink deposit, garment, color of garment, artwork, and desired effect

-

The ink cures at 260°F for 70 seconds or at 450° with a flash

-

The mesh range is 86 mesh/inch to 305 mesh/inch

-

Flexible, soft, and has excellent opacity on dark color garments

-

Bleed and crack resistant

-

No catalyst needed

-

Will not shrink or melt heat sensitive materials (nylon, non woven bags, polypropylene, etc.)

-

Adheres to thicker fabrics (50% cotton/ 50% polyester sweatshirts)

-

Covers fibers on 100% cotton

-

Prevents Dye Migration on 100% polyester, 50/50 sweatshirts, and sublimated polyester

-

Can be used as a transfer ink and foil adhesive

-

Prevents the elimination of toxic atoms from PVC Polymer and the formation of HCI (Hydro-Chloride Gas)

-

You may no longer need ink cleaners made with petro-chemicals such as blended solvents

-

Saves energy, consumption, and space

-

Reduces energy bill and emissions

-

Increases production

3 Tips for Screen Printing with White Fusion 180° Ink

-

Not as much white ink is required to achieve good coverage on light color garments

-

Use an underlay screen of ink on dark color garments for best results

-

The height between the screen mesh and the substrate you are printing on should be 1/8 of an inch since white tends to be thicker

-

FUSION 180 WHITE

-

FUSION 180 STOCK COLORS

-

FUSION 180 METALLIC

4. Fusion Bond

Fusion Bond is phthalate free plastisol ink with a coupling/bonding component. Fusion bond makes the ink behave as if it has a catalyst yet does not have one and stays soft. A direct screen print will stick to heat sensitive coated materials. The ink cures at 220°F -240°F. Fabrics that can stand the heat of a flash can be cured with a flash at 450°F for 4 seconds. This includes polyester and cotton bags. Fusion bond was specially formulated with coupling capability for a revolutionary transfer method that eliminates weeding on colored garments.

Benefits:

-Flash cure on all fabrics without catalyst

-Cure with a dryer at 220°F -240°F without catalyst

-Strong adhesion for direct screen print or transfer on cotton, polyester, nylon and coated materials

-Coupling capability with color laser toner (RICOH ProC5200s for best results)

-Strong wash durability

FUSION BOND

5. Fusion Bond Transfer

Fusion bond transfer is a four-color process transfer that sticks to all garments at 310 degrees Fahrenheit for 5 seconds. After you wait 15 seconds you can peel the transfer off of the garment.

BENEFITS:

-

This new transfer blocks migration even on sublimated fabrics.

-

The process does not require weeding, cutting, or an under base transfer step

-

There is great stretch for spandex products.

REQUIREMENTS:

-

11.5″ by 16″ Image Area

-

Group Images on Artwork

-

We have a minimum of 12 sheets.

-

Please send art to [email protected]

-

Upon review of artwork, an additional art charge may apply

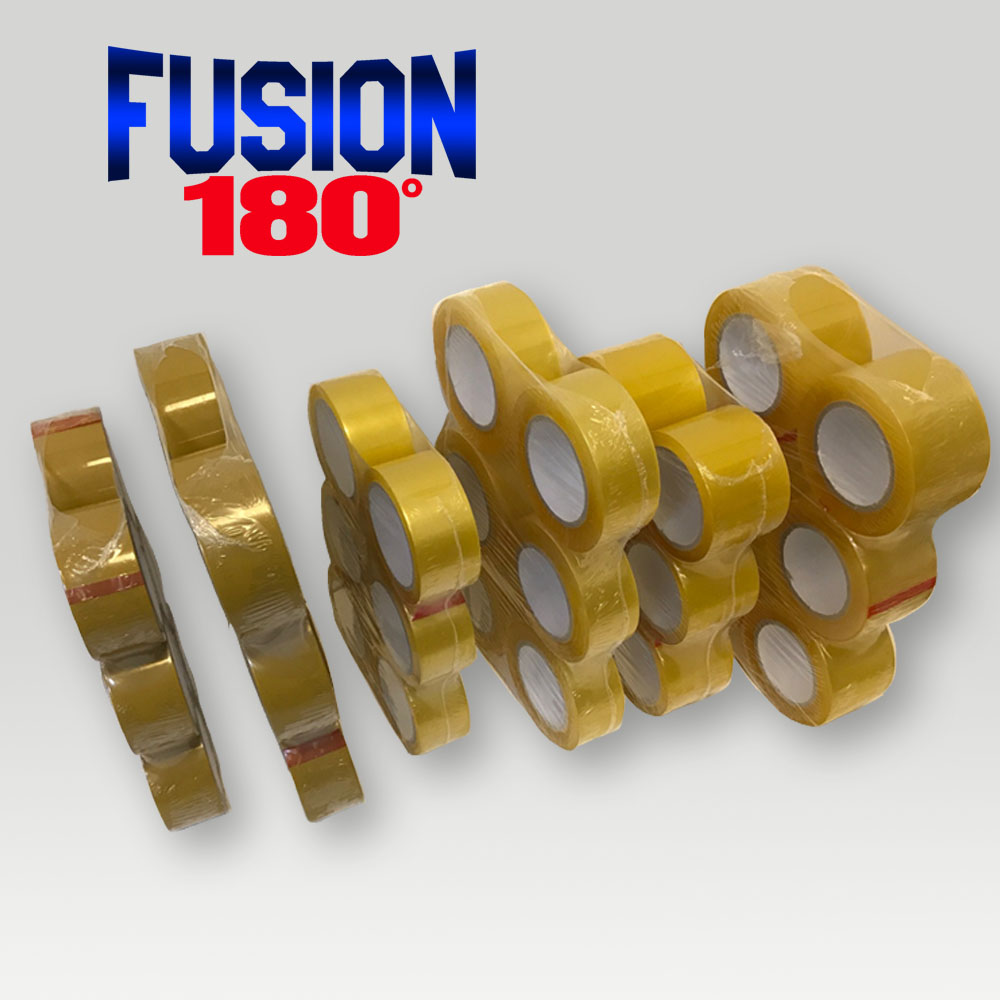

6. Packing Tape

Our packing tape is made out of Polypropylene and Polyisophorone. Adhesive is made of natural rubber. This natural rubber will last longer than water soluble acrylic in hot and cold weather. The tape will not peel and one application will be enough to hold the package closed. PACKING TAPE

-

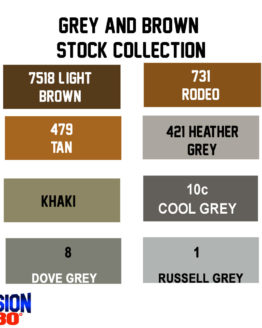

Grey and Brown Stock Collection$29.95 – $459.95

Grey and Brown Stock Collection$29.95 – $459.95 -

Purple and Pink Stock Color Collection$29.95 – $459.95

Purple and Pink Stock Color Collection$29.95 – $459.95 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Green Fusion 180 Stock Color Collection$29.95 – $459.95

Green Fusion 180 Stock Color Collection$29.95 – $459.95 -

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50 -

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95 -

Red Fusion 180°Ink Stock Collection$29.95 – $459.95

Red Fusion 180°Ink Stock Collection$29.95 – $459.95 -

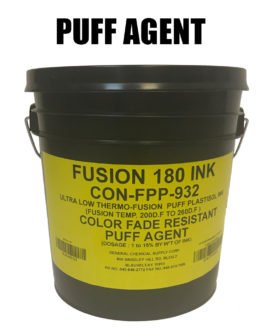

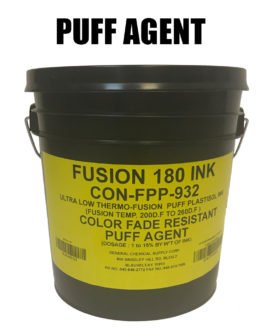

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

-

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

CFB100- Cotton White Ink$18.00 – $320.00

CFB100- Cotton White Ink$18.00 – $320.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00 -

FUSION 180° METALLIC INK$69.00 – $269.00

FUSION 180° METALLIC INK$69.00 – $269.00 -

FUSION 180° FLUORESCENT INK$36.50 – $579.95

FUSION 180° FLUORESCENT INK$36.50 – $579.95 -

FUSION 180° SHIMMER INK$45.00 – $500.00

FUSION 180° SHIMMER INK$45.00 – $500.00 -

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

-

INKJET MEDIA FILM SHEETS$55.49 – $111.19

INKJET MEDIA FILM SHEETS$55.49 – $111.19 -

Inkjet Media Film$45.59 – $84.29

Inkjet Media Film$45.59 – $84.29