Our Cotton white ink covers fibers on cotton, cures at 270 degrees F, and has excellent opacity!

4 Ways to Stay Motivated to Grow Your Business Having a positive mindset, revisiting your purpose, setting and achieving goals, and taking regular breaks are four of the best ways to stay motivated and grow your business. Always remember, that there is no failure! Also, keep in mind that failure is your perception. Most people […]

7 Fabrics Low Cure Ink Adheres to Why use low cure biodegradable white ink? Fusion 180 ink adds miraculous Bio Base to the entire ink system. Bio Base makes the ink biodegradable and soft, improving viscosity. Fusion 180 ink with Bio Base remains low cure stays soft longer and flows beautifully through fine meshes without sacrificing coverage. […]

Promotional items can be super trendy! T-shirts, mugs, and water bottles are some of the most common promotional items. Listed below are 15 ideas of products that you can add to your shop to help your customers promote their business. Tote Bags Sunglasses Pens Hats Umbrellas Apparel (Raincoats, Sweatshirts, Tanks, T-shirts, ETC.) Backpacks Mugs Coozies […]

Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save […]

4 Ways to Grow Your Screen-Printing Business Growing your business while maintaining your current customer base should always be a top priority. Below we will list a few ways on how you can do this! Promotional Items- Make sure your current customers’ promotional needs are being met. Offer your customers a wide variety of products […]

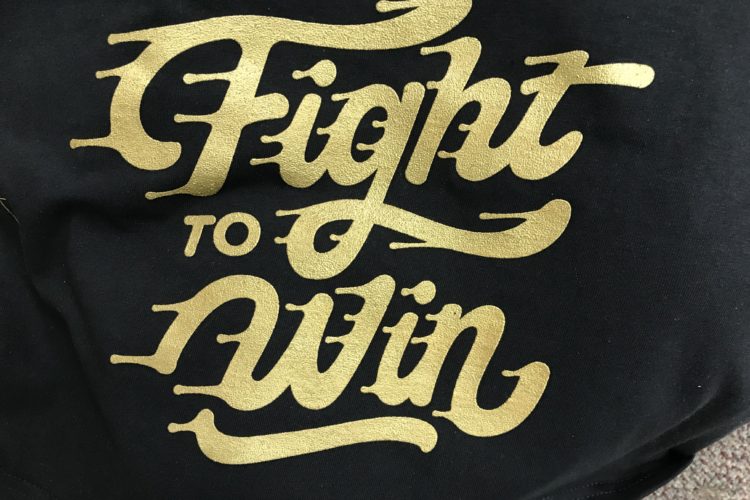

Top 8 Prints with Our New Biodegradable Ink! Low cure ink is the solution to all of your print life issues including printing on heat sensitive materials. Our ink is now biodegradable and is still super soft and creamy. -The ink works on all fabrics -You do not need a catalyst and you do not […]

Shop by category: White Ink | Black Ink | Red Stock Color Collection | Orange Stock Color Collection | Yellow Stock Color Collection | Green Stock Color Collection | Blue Stock Color Collection | Purple/Pink Stock Color Collection | Grey/Brown Stock Color Collection | Metallic Ink | Fluorescent Inks | Glow in the Dark […]

ATTENTION!!! Fusion 180 ink adds miraculous BIO BASE to entire ink system. Bio Base makes the ink biodegradable and soft, improving viscosity. Fusion 180 ink with BIO BASE remains low cure stays soft longer and flows beautifully through fine meshes without sacrificing coverage. Try it today!! Email us at [email protected] for a sample! Background: […]

Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save […]