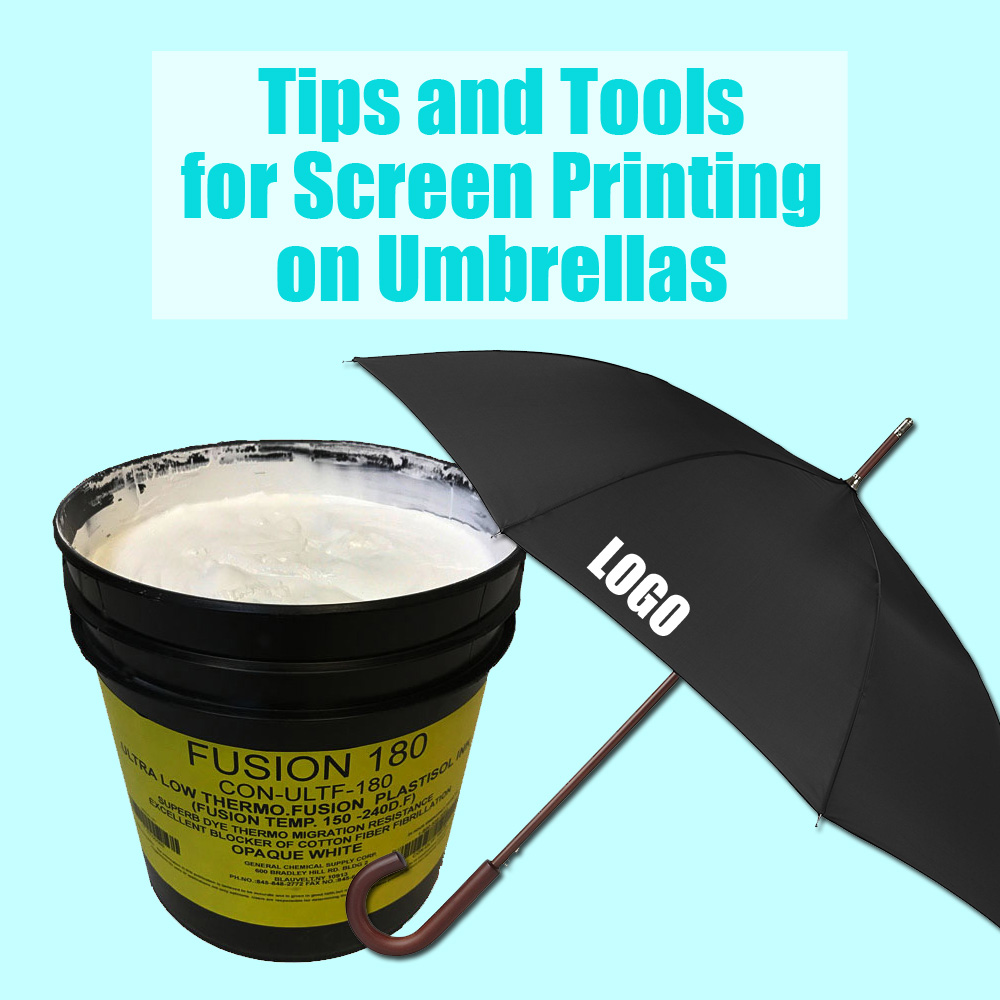

Adding custom screen-printed umbrellas to your screen print shop product line is an excellent idea, as this item can appeal to any client. From parents and fans who would like to show team spirit to small businesses or corporations looking to gift branded items.

With our simple tips and switching to Fusion 180 Ink, you can add umbrellas to your promotional product line and will be able to screen print on this item without running into any challenges.

Screen Printing.

Most umbrellas are made with nylon, meaning regular plastisol-based ink will sit on top of the fabric and will not bond with the material. Our low-temperature ink is a perfect option for screen printing on umbrellas. You will not need to pre-heat the fabric prior to printing, as pre-heating will lead to shrinking the synthetic fabric. You do not need to use an adhesive or any additives. This means you will not have to worry about the ink expiring. We recommend gelling the ink with a flash cure unit prior to removing it from the press. You will know that our ink has gelled because the print will turn from glossy to matte. You do not need to give the ink time to set, as with the low temperature the ink will have been completely bonded to the umbrella.

Transfer.

We also recommend screen-printed transfers on umbrellas. Our ink works well as a heat transfer and you will not even need a catalyst or worry about ink expiring. Use a smaller pallet similar to make the job easier, don’t preheat the umbrella, use heat-resistant tape to hold the umbrella to the pallet so that the item will not shift, and don’t use as much pressure to transfer onto an umbrella. Fusion Bond transfers are the solution if you have a multi-color image to reproduce on an umbrella.

10 Facts About Fusion Bond Transfer:

1. Fusion bond transfer is a four-color process transfer that sticks to all garments at 310 degrees Fahrenheit for 5 seconds.

2. After you wait 15 seconds you can peel the transfer off of the garment.3. The outcome is bright and durable.

4. This new transfer blocks migration even on sublimated fabrics.

5. The process does not require weeding, cutting, or an under-base transfer step.

6. There is a great stretch for spandex products.

7. Group images of artwork on an 11.5″ by 16″ image area. We have a minimum of 12 sheets.

8. Please send art to [email protected] at 300 resolution

9. Upon review of artwork, an additional art charge may apply.

10. Results are a SOFT HAND!

Similar Blog Posts:

-7 Facts About Low Temperature Ink

–5 Step Guide for Screen Printing on 50/50 Sweatshirts

–4 Promotional Products to Add to Your Screen Print Shop Product Line

-

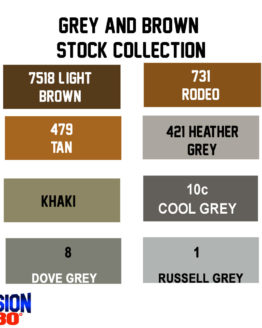

Grey and Brown Stock Collection$29.95 – $459.95

Grey and Brown Stock Collection$29.95 – $459.95 -

Purple and Pink Stock Color Collection$29.95 – $459.95

Purple and Pink Stock Color Collection$29.95 – $459.95 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Green Fusion 180 Stock Color Collection$29.95 – $459.95

Green Fusion 180 Stock Color Collection$29.95 – $459.95 -

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50 -

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95 -

Red Fusion 180°Ink Stock Collection$29.95 – $459.95

Red Fusion 180°Ink Stock Collection$29.95 – $459.95 -

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

-

INKJET MEDIA FILM SHEETS$55.49 – $111.19

INKJET MEDIA FILM SHEETS$55.49 – $111.19 -

Inkjet Media Film$45.59 – $84.29

Inkjet Media Film$45.59 – $84.29 -

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00 -

FUSION 180° METALLIC INK$69.00 – $269.00

FUSION 180° METALLIC INK$69.00 – $269.00 -

FUSION 180° BLACK INK$29.95 – $2,145.00

FUSION 180° BLACK INK$29.95 – $2,145.00 -

FUSION 180° FLUORESCENT INK$36.50 – $579.95

FUSION 180° FLUORESCENT INK$36.50 – $579.95 -

FUSION 180° SHIMMER INK$45.00 – $500.00

FUSION 180° SHIMMER INK$45.00 – $500.00 -

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95