TIPS FOR SCREEN PRINTING WITH METALLIC LOW CURE INK!

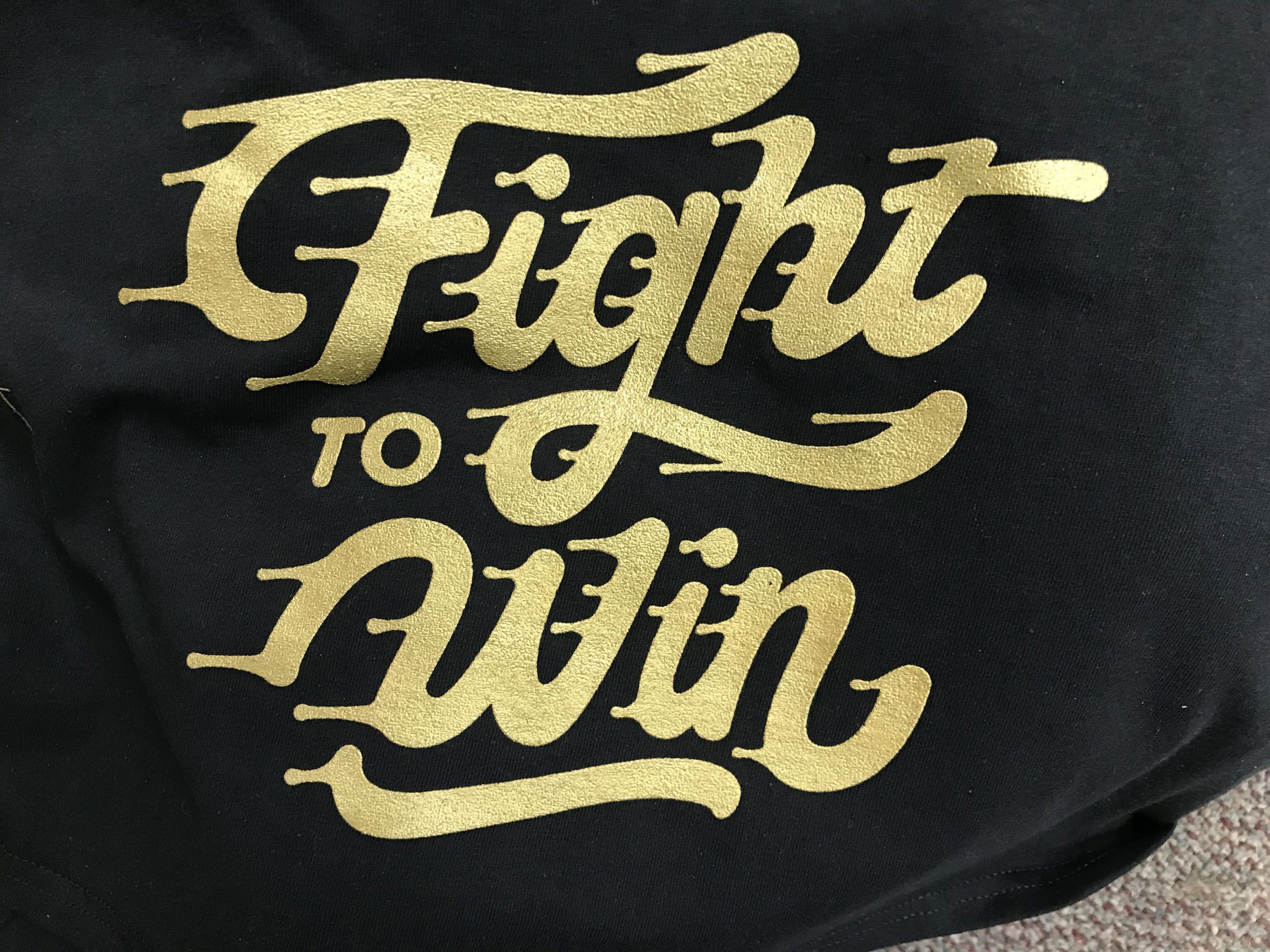

Our foil grade metallic ink comes in handy for a shiny and bright print. The ink contains actual metallic flakes that are added within the ink, creating a metallic look to your print. We have two options available either metallic gold or silver. The below print is metallic gold ink on 100% cotton black long sleeve shirt. For this print, we used 86 mesh two times.

2 Tips:

1. We recommend using 86-158 mesh and cure at 260°F through the dryer.

2. Metallic Inks take longer to cure because the metallic flakes in the ink reflect the heat of the dryer.

13 Facts About Low Cure Ink:

- Flexible, soft, and has excellent opacity on dark color garments

- Bleed and crack resistant

- No catalyst needed

- Will not shrink or melt heat sensitive materials (nylon, non woven bags, polypropylene, etc.)

- Adheres to thicker fabrics (50% cotton/ 50% polyester sweatshirts, raincoats, etc.)

- Covers fibers on 100% cotton

- Prevents dye migration on 100% polyester, 50/50 sweatshirts, and sublimated polyester

- Can be used as a transfer ink and foil adhesive

- Prevents the elimination of toxic atoms from PVC Polymer and the formation of HCI (Hydro-Chloride Gas)

- You may no longer need ink cleaners made with petro-chemicals such as blended solvents

- Saves energy, consumption, and space

- Reduces energy bill and emissions

- Increases production