Introduction

Introduction

Printing on a tri-blend shirt can bring difficulties for any screen printer. Screen printers need to know how to print on this substrate, as they are becoming a popular item in the fashion industry. Following our guide will enable you to print on a tri-blend without running into any challenges.

The Basics

Tri-blend t-shirts are a 50-25-25 mix of polyester, cotton, and rayon. These shirts are comfortable and create a soft blend that customers love. They have a heather appearance and can be hard to print on.

The Challenges

The blends of three different fabrics reach new difficulties, as each individual material comes with its own special quality. Some common challenges are listed below and the solution to those challenges.

1. Dye Migration – When polyester is heated at high temperatures (325°F) the dye turns to gas. This causes plastisol ink dye migration problems. The sublimated dye can alter the colors of the ink. However, with Fusion 180 Ink this will no longer be an issue, as you cure our low temperature ink at 260° F for 40 seconds through the dryer.

2. Print Distortion- Tri Blend fabrics are stretchy, soft, and comfortable. However, you need to be careful not to stretch the garment when loading the tri-blend. This will prevent the item from becoming a distorted print.

3. Burning- Rayon burns at a high temperatures. This makes it very easy to melt a tri-blend shirt. However, with Fusion 180 this will not occur. You will be able to print at the low cure temperature without melting, shrinking, or scorching the item.

4. Uneven Ink Texture- A tri-blend garment and regular plastisol based ink is going to interact with the fabric and create an uneven print. Fusion 180° has a soft, flexible, and even feel to all prints on any garment. The ink will work on 100% cotton, 50/50, tri-blend, polyester, etc.

Tips for Printing on Tri-blend Fabrics

– Avoid using an under-base, as this requires curing with a flash

– Print wet on wet onto a tri-blend fabric

– Select the proper low cure Fusion 180 Ink to avoid dye migration, distortion, and melting

– Create a light-weight vintage print with the tai-blend fabric with one stroke

– Carefully load your press, as the fabric is stretchy

– Cure for the proper amount of time and at the right temperature to avoid dye migration

Conclusion

It takes special care to screen print successfully on a trip-blend garment, but with practice you will be able to achieve a beautiful print that your customers will be amazed by. Tri-blends are a perfect fabric for customers who are seeking a vintage look. Offering tri-blend will attract new customers who are looking for this premium product.

-

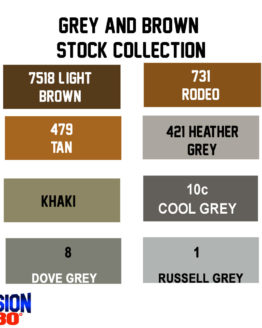

Grey and Brown Stock Collection$29.95 – $459.95

Grey and Brown Stock Collection$29.95 – $459.95 -

Purple and Pink Stock Color Collection$29.95 – $459.95

Purple and Pink Stock Color Collection$29.95 – $459.95 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Green Fusion 180 Stock Color Collection$29.95 – $459.95

Green Fusion 180 Stock Color Collection$29.95 – $459.95 -

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50 -

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95 -

Red Fusion 180°Ink Stock Collection$29.95 – $459.95

Red Fusion 180°Ink Stock Collection$29.95 – $459.95 -

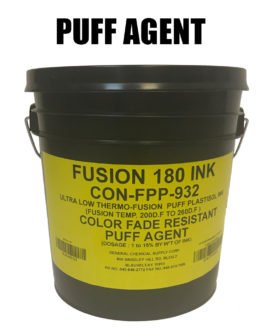

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00